Willkommen bei ARNTZ - Sägebänder Made in Germany

Ihr Experte für die Zerspanung der unterschiedlichsten Metalle

230 Jahre Metallverarbeitung, 230 Jahre Werkzeuge, 230 Jahre Leidenschaft: Mit Stolz blicken wir auf eine lange Tradition. Gleichzeitig schauen wir mit Begeisterung in die Zukunft. Neue Märkte werden mit komplexeren Materialien erschlossen und die Legierungen ändern sich mit den steigenden Anforderungen an die daraus gefertigten Produkte.

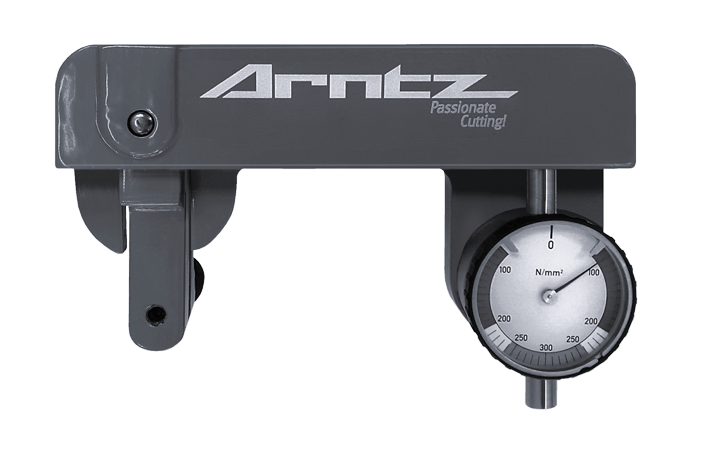

Das erfordert neue, innovative Lösungen in der Sägetechnik. Unsere Spezialisten stellen sich Tag für Tag den Aufgaben und Herausforderungen der unterschiedlichen Märkte. Wir kennen die Materialien und ihre Querschnitte – branchenübergreifend und bis ins kleinste Detail.

Unsere Strukturen erlauben uns, schnell und individuell auf die speziellen Wünsche unserer Kunden einzugehen und in enger Zusammenarbeit mit ihnen optimale Lösungen zu entwickeln. Von der ersten Anwendungsberatung bis zum Finetuning sind wir für Sie da. Bei Bedarf auch bei Ihnen vor Ort.

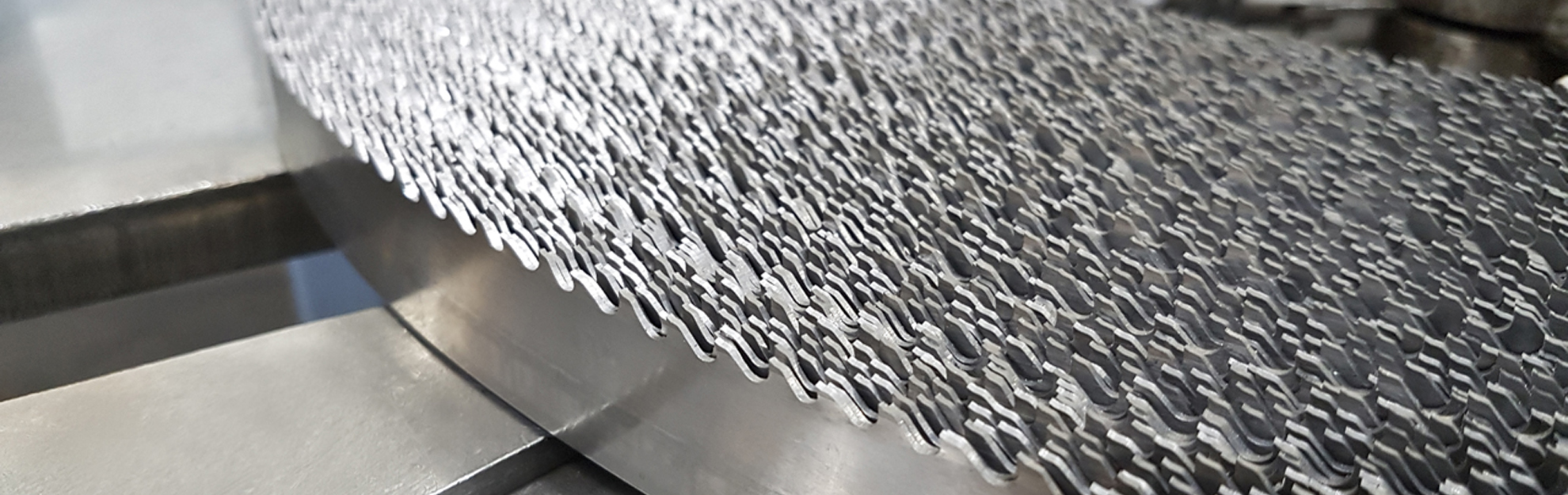

Sägebänder von ARNTZ sind Hochleistungsprofis – wirtschaftlich, präzise und exakt auf die jeweilige Anwendung abgestimmt. Ein hoher Qualitätsanspruch und die Leidenschaft für unsere Arbeit bestimmen unser Handeln. Wir liefern weltweit Sägetechnik „Made in Germany“, auf die Sie sich verlassen können – Ehrensache!

Produkte

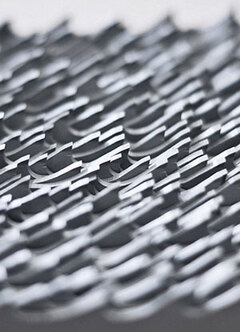

Bi-Metall-Sägebänder