ARNTZ Carbide Tipped Band Saw Blades – Why are they so successful?

ARNTZ Carbide Tipped Band Saw Blades are specialists in difficult-to-machine materials with high alloys and strength, making them suitable for the most demanding sawing tasks that require maximum precision.

Our Carbide Saw Blades provide up to 3 times higher cutting performance, resulting in significant shorter cutting times. At the same time, they convince with particularly long service lives – a more efficient utilization of the sawing equipment saves costs. Due to shorter cutting times, a higher material throughput and a larger cutting capacity can be achieved.

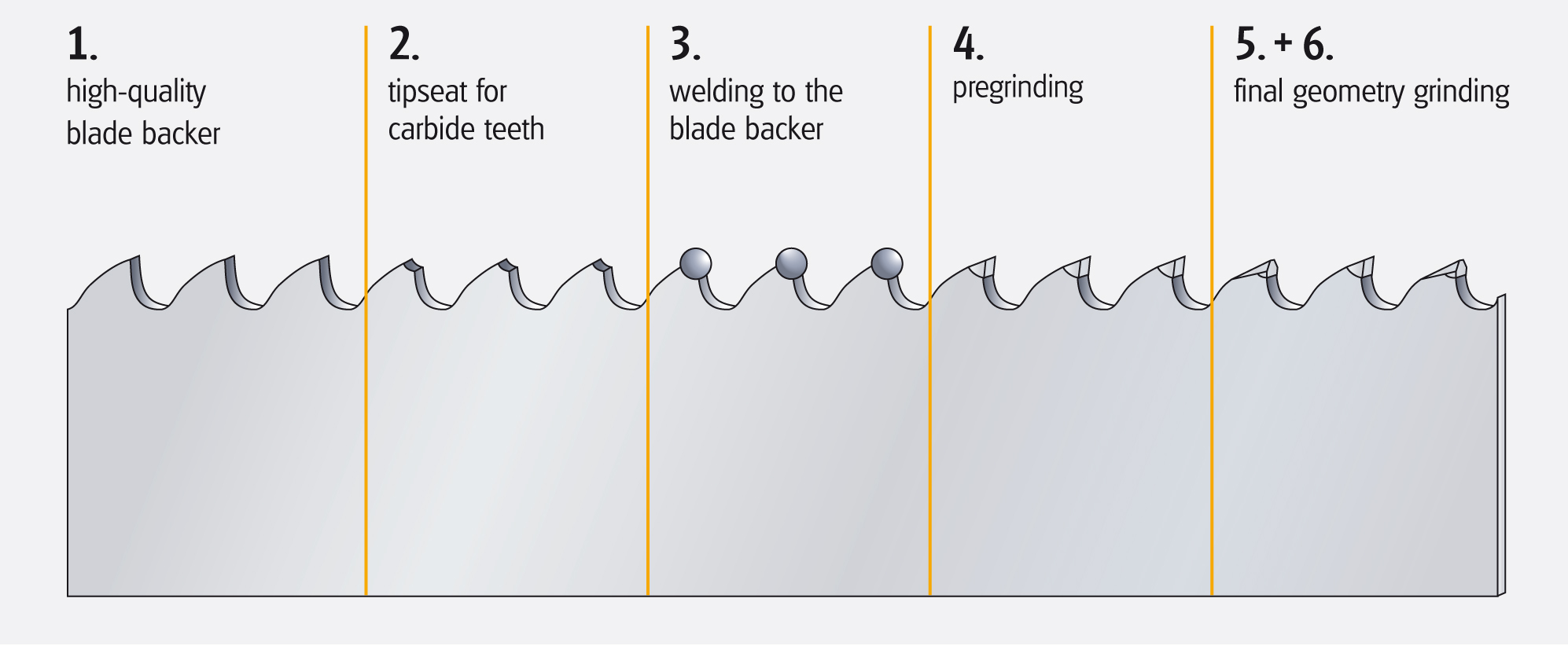

Carbide band saw blades go through a special manufacturing process:

1. The blade backer is made of specially alloyed spring steel.

2. Mechanical insertion of the tipseat for carbide teeth.

3. Carbide teeth are welded onto the blade backer in a special process.

4. Using high-precision grinding technology, the hard metal teeth receive the basic grinding on the tooth face and flanks.

5.+6. In the final grinding, the hard metal teeth are given application-specific tooth geometries, with the back of the tooth being brought into the special tooth shape. The different cutting geometries ensure low-vibration cuts and smooth material surfaces.

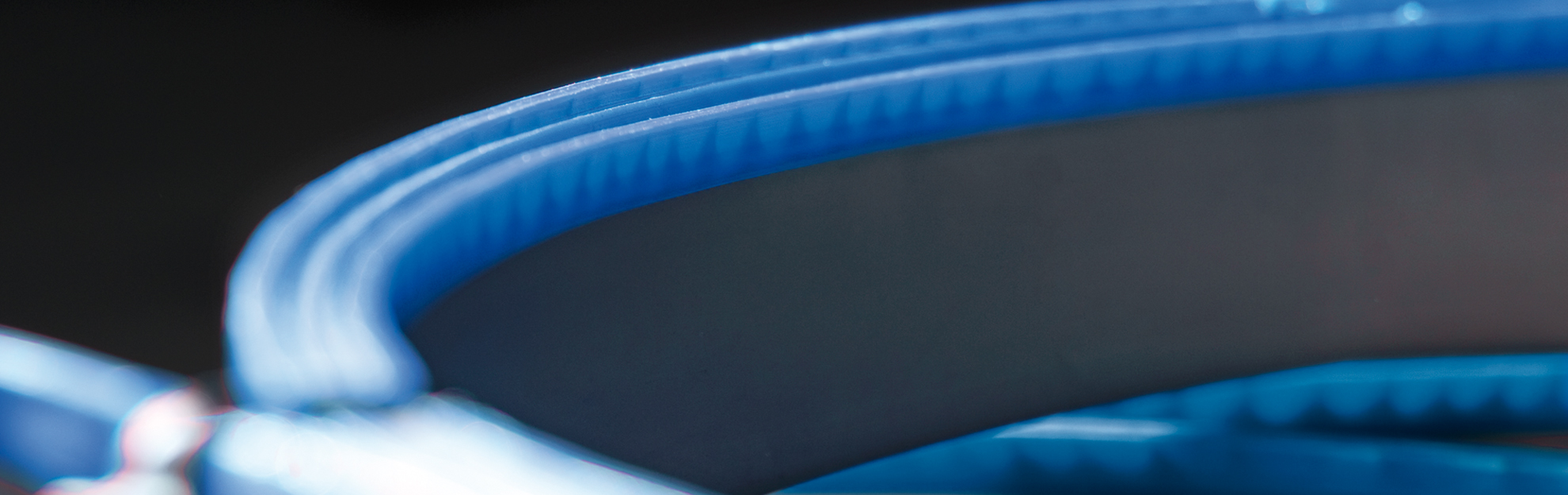

Thus the pre- and post-cutter geometry of the 643 BLUE-LINE is ideally suited for the machining of non-ferrous metal and graphite.

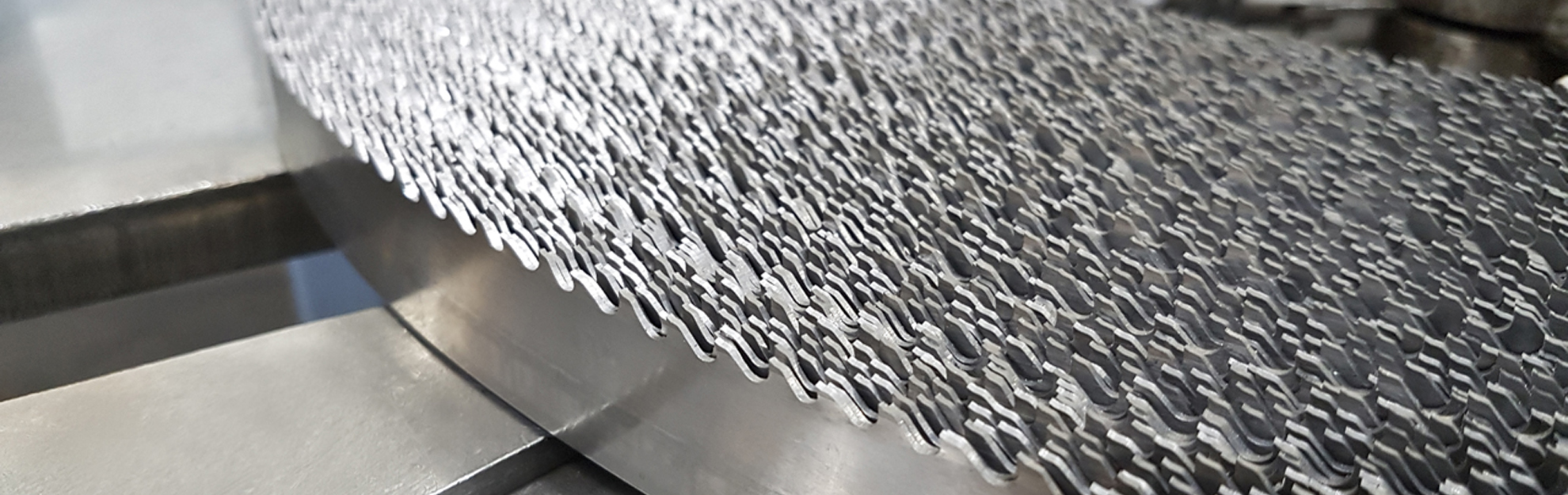

On the other hand, the 650 SILVER-LINE impresses with its powerful multi-chip tooth geometry and is the specialist for hardened steels up to 1900 N/mm2 as well as exotic, difficult-to-machine alloys.

Convince yourself: Get your offer!